COIL Stories

Green Bowl Foods

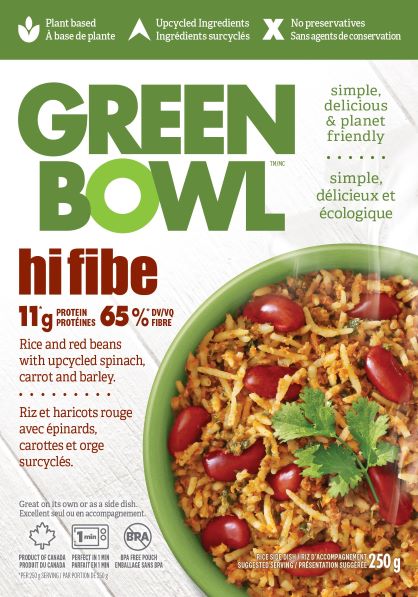

Producing a line of upcycled Ready to Eat meals

The winner of the second Circulate CoLab cohort was a collaboration led by Green Bowl Foods (previously Revived Foods), announced in September 2022. Based in Aurora, Ontario, Green Bowl is producing a line of Ready-to-Eat (RTE) meals made from 25 to 30% upcycled ingredients. They worked with Market Brewing Company, Greenhouse Juice and Saina+ Consulting to prototype two RTE meals – rice & bean and rice & chickpea – throughout the CoLab. The meals include 10-15% spent grants from Market Brewing and 15-20% upcycled vegetable pulp from Greenhouse Juice. Future upcycled RTE meals are projected to diversify into soups, quinoa and pastas.

The Impact

Emerging Markets: The RTE meal industry is quite competitive. Future Market Insights reports that the global RTE market is expecting “robust” growth, registering a compound annual growth rate (CAGR) of 7.7% and a projected USD $3.778M value by 2032.

Upcycling Nutrition: Core to this work was food waste diversion, energy and resource efficiency, and nutritional value. Working with producers and processors across the supply chain, these RTE meals, when scaled, will divert massive amounts of food waste from breweries, juicing companies, and more.

Green Jobs: The team is looking to ramp up production to 1,150,000 units over the next year in a new facility, creating an estimated 8 new jobs. Conversations with retail outlets and chains have already begun, and Green Bowl aims to be on retail shelves across Ontario by mid 2023.

How they made it work

Core to this work was food waste diversion, energy and resource efficiency, and nutritional value. Working with producers and processors across the supply chain, these RTE meals, when scaled, will divert massive amounts of food waste from breweries, juicing companies, and more.

For context, Greenhouse Juice produces 75 tonnes of juice pulp annually, and Market Brewing produces 5.5 tonnes of spent grains. Tapping into this resource stream of by-products – which have already been cleaned, washed, and ground – also decreases energy and water intensity.

Further, because the meals are shelf-stable, they require no cold chain solution for transportation or for at-home storage.

Lastly, their R&D process revealed that spent grain and vegetable pulps are high and affordable sources of fibre and protein, and the nutritional value of Green Bowl’s upcycled RTE meals is much greater than similar shelf-stable or frozen meals using virgin ingredients.

“To produce shelf-stable, upcycled RTE meals, a combination of creativity, science, experience, and passion is required.” – Max Jamshidian, Green Bowl Foods Founder