COIL Stories

CoLab: Upcycled Whole Plant Powders

CoLab Team Members:

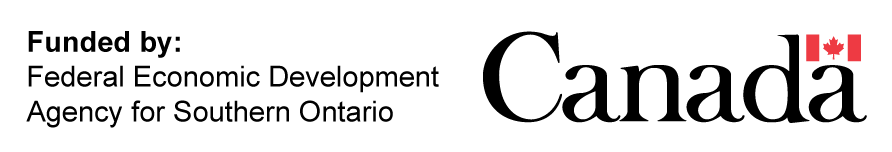

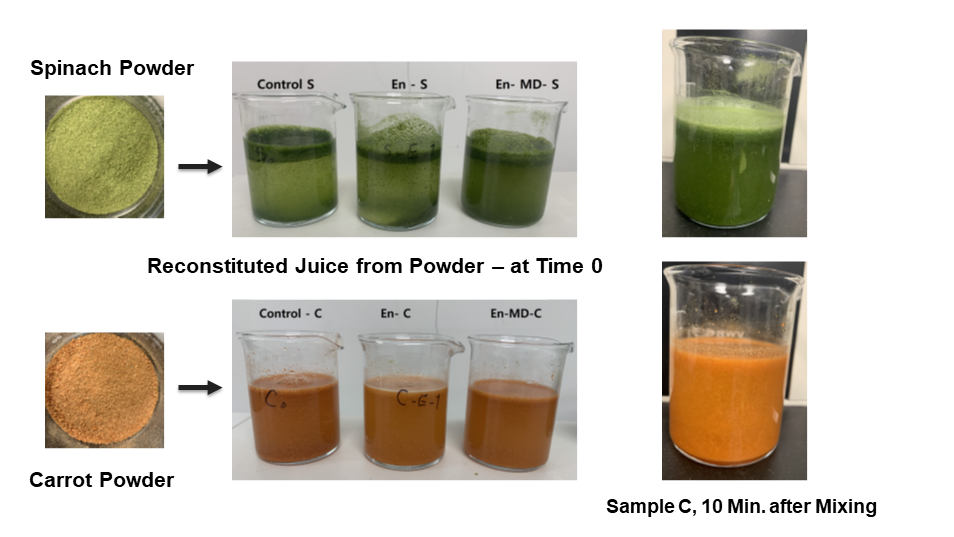

Troubled by the 75 annual tonnes of organic by-product from their juicing process, Greenhouse Juice has teamed up with Herbert Labs and SAINA+ to find a solution. As a company that has prioritized organic and non-GMO ingredients and sustainable glass bottling since its inception in 2014, the challenge was not just about waste reduction, but also creating something that was as nutritious, delicious, and convenient as their customers have come to expect from their products. Enzymatic treatment prototyping has successfully produced a whole plant powder for juices, teas and other applications.

As the first-place winner of COIL’s Circulate CoLab in 2022 and recipient of $100,000 in Demonstration Project funding for the next year, great learnings are expected to come out of this trio.

The Impact

Nutrition preservation: Enzymatic treatment, prototyped during the COIL CoLab, is a critical step in preserving and even increasing the nutritional value of organic fruit byproducts, especially soluble fibre.

Cost-saving & convenient: Dehydration of organics into powders sustains nutritional values, extends shelf-life and reduces product weight by 65%, therefore reducing packaging and minimizing cold-chain requirements.

Application across industries: the dehydration process prototyped has versatile applications well beyond cold-pressed juices, including dairy, baking, cereal goods, baby foods, cosmetics and even medical materials.

How they made it work

Centre problem-solving: this team was built with an intentional focus on problem-solving strategies and investment into training and professional development that ultimately supports business sustainability and profitability.

Find the right experts: throughout the CoLab process, the team was connected with food innovation mentors and other small businesses and entrepreneurs who supported their drying process and opened up additional experiments with fermentation.

Invest in R&D: the team increased R&D from 20% to 30% of their overall budget to provide additional sources and dedicated project management, and leave room for experimentation.

“The circular economy offers a real opportunity to improve the way you do business by minimizing waste within your services. To make it happen, try to understand who you want to influence, describe the context, define your circular economy idea, learn from the success of others and do your part.”- Behnoush Maherani, Director of Research & Development, Greenhouse Juice Company

“We really appreciate the opportunity [COIL] gave us: a framework within which to step out of our business day-to-day and concentrate on something forward-looking and entirely new.”– Anthony Green, Co-Founder, Greenhouse Juice